The factory floor is often buzzing with activity. Machines are humming as parts swiftly move down the production line, and everything seems to be running smoothly. That is, until without warning, a critical piece of equipment fails. The unexpected downtime costs thousands of dollars per minute, disrupting production and throwing schedules off track. For factory managers, this scenario is all too common. Predicting machinery failures to prevent costly disruptions has long been a challenge as traditional maintenance methods are reactive, relying on manual checks that often miss early warning signs.

At Sapphire Ventures, we believe predictive maintenance, powered by cutting-edge sensor technology and AI, is key to transforming industrial operations. That’s why we’re thrilled to partner with Igor Marinelli, CEO of Tractian, to lead the company’s Series C round. We believe Tractian’s innovative combination of advanced hardware and intelligent software is revolutionizing how factories avoid unplanned downtime and streamline their maintenance processes, setting a new standard for operational efficiency.

Responding to a Painful Status Quo in Industrial Maintenance

Industrial maintenance is facing a growing crisis. Unplanned downtime, once considered a manageable disruption, now costs the world’s 500 largest companies 11% of their revenues—equivalent to $1.4 trillion annually, or the GDP of a major industrial nation like Spain. In the automotive sector, the cost of an idle production line at a large plant has surged to $695 million annually, a 1.5x increase over the past five years, while downtime in heavy industry plants has risen to $59 million per year, 1.6x higher than in 2019.

Recovery times from downtime have also lengthened significantly. Five years ago, it took an average of 49 minutes to get production running again; today, it takes 81 minutes. This 65% increase is driven by three major systemic challenges:

- Labor Shortages: The post-COVID “Great Resignation” created a skills gap in maintenance teams.

- Supply Chain Delays: Replacement parts take longer to source and arrive, extending downtime.

- Complex Failures: Equipment breakdowns are increasingly harder to detect and repair.

Traditional maintenance methods compound the issue. Reactive approaches wait for problems to occur, while preventive schedules fail to account for real-time wear and tear. This leads to overspending on unnecessary repairs or devastating costs from unexpected breakdowns.

The upside of addressing these challenges is enormous. Siemens estimates that fully adopting predictive maintenance practices could save Fortune Global 500 companies 2.1 million hours of downtime annually, increase productivity by 5%, and reduce maintenance costs by 40%, resulting in savings of over $600 billion.

This is where Tractian comes in. By combining advanced AI, real-time data, and intelligent software, the company empowers teams to detect issues early, take proactive measures and significantly reduce downtime. It’s not just about predicting failures—it’s about transforming maintenance into a streamlined, cost-efficient advantage.

Meet Tractian: The Manufacturing Copilot

Tractian addresses the core challenges in industrial maintenance with a solution designed to close the human-to-machine knowledge gap. As a leading industrial AI platform, Tractian empowers maintenance engineers, reliability professionals, and machine operators with the tools and insights needed to monitor, predict and act on machinery performance in real time.

At the heart of Tractian’s platform is its ability to integrate real-time data from industrial equipment and translate it into meaningful insights. Through advanced AI and predictive algorithms, the system identifies early signs of potential failures and suggests preemptive actions. This proactive approach helps reduce dependency on specialized knowledge, enabling teams to act confidently even amid labor shortages or skill gaps.

The more data Tractian processes, the smarter it becomes. Its AI continuously learns from operational patterns, refining its predictions and enhancing its ability to optimize maintenance strategies. This creates a self-improving platform that not only anticipates issues but also adapts to evolving operational needs, further driving value for industrial operators.

By bridging the gap between people and machines, Tractian provides a powerful solution that levels the playing field for the modern industrial workforce. It’s not just about predicting failures—it’s about equipping teams with the tools to transform maintenance into a competitive advantage.

Thrilled to Back Tractian’s Visionary Team

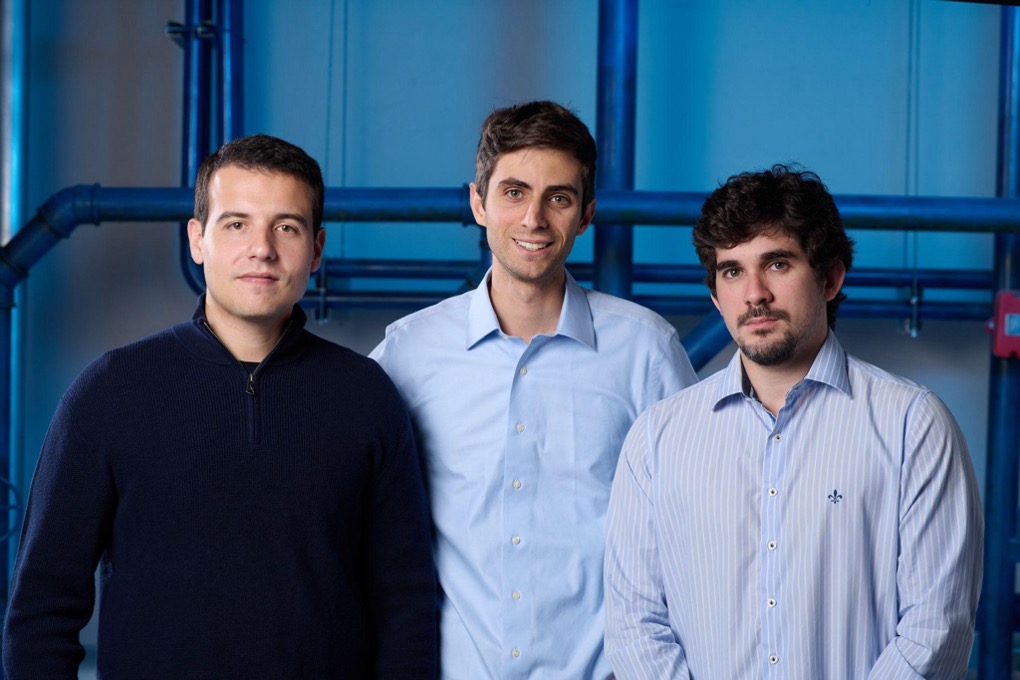

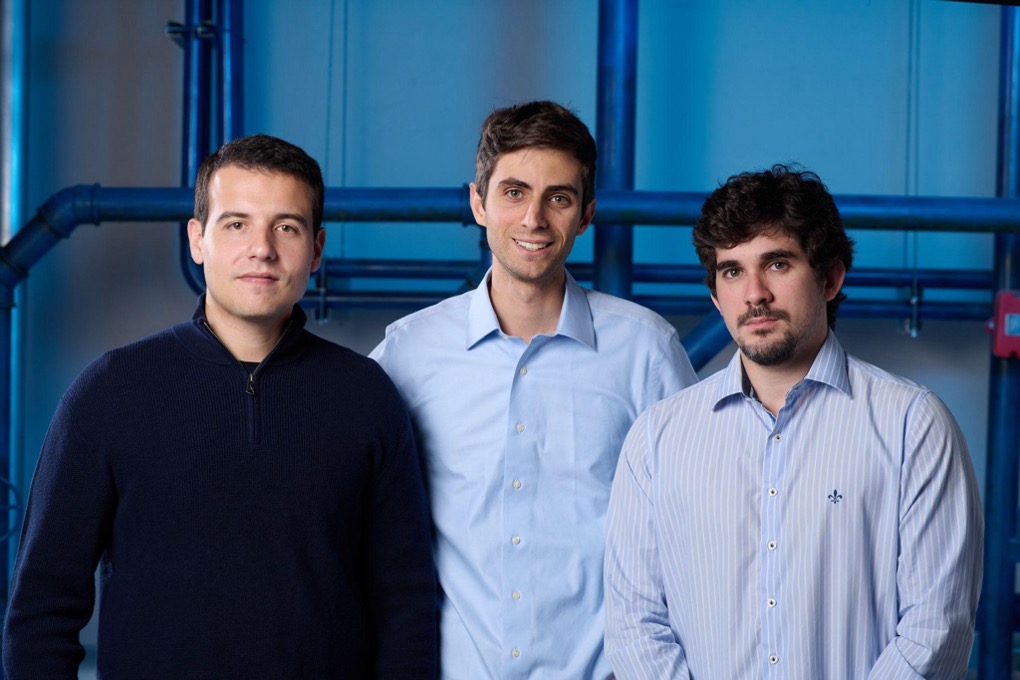

From left to right: Gabriel Lameirinhas (Founder, Co-CEO), Igor Marinelli (Founder, CEO), and Leonardo Vieira (Founder, CEO Mexico)

At Sapphire Ventures, we take pride in partnering with exceptional founders who bring unique perspectives and deep commitment to solving complex problems. Tractian’s founding trio—Igor Marinelli, Gabriel Lameirinhas and Leonardo Vieira—share a deep-rooted connection to the manufacturing industry, having grown up around factory floors and witnessing its challenges firsthand. Particularly for CEO Igor Marinelli, watching his father work as a maintenance technician at a paper mill, sparked his passion to transform the future of manufacturing. Together, they form a visionary team reshaping industrial maintenance, and we at Sapphire are honored to support their transformative journey.

Tractian’s rapid growth and adoption by leading industrial players around the globe underscore the significant demand for its solutions. We’re excited to support Igor and his team’s mission to eliminate unplanned downtime, revolutionizing the way companies maintain their equipment. If you’re interested in learning more about Tractian’s platform or joining the growing team, check out the Tractian website for more information.

Legal disclaimer

Nothing presented within this article is intended to constitute investment advice, and under no circumstances should any information provided herein be used or considered as an offer to sell or a solicitation of an offer to buy an interest in any investment fund managed by Sapphire Ventures (“Sapphire”). Information provided reflects Sapphires’ views as of a time, whereby such views are subject to change at any point and Sapphire shall not be obligated to provide notice of any change. Companies mentioned in this article are a representative sample of portfolio companies in which Sapphire has invested in which the author believes such companies fit the objective criteria stated in commentary, which do not reflect all investments made by Sapphire. A complete alphabetical list of Sapphire’s investments made by Its direct growth and sports investing strategies is available here. No assumptions should be made that investments described were or will be profitable. Due to various risks and uncertainties, actual events, results or the actual experience may differ materially from those reflected or contemplated in these statements. Nothing contained in this article may be relied upon as a guarantee or assurance as to the future success of any particular company. Past performance is not indicative of future results.