Over the last few years, a series of shockwaves has sent supply chains into a state of disarray. Wave after wave has hit, including a global pandemic, war, labor shortages, congested ports, product recalls and more. These disruptions have been rippling across the world, driving home to consumers and business executives the critical importance of something we once all took for granted.

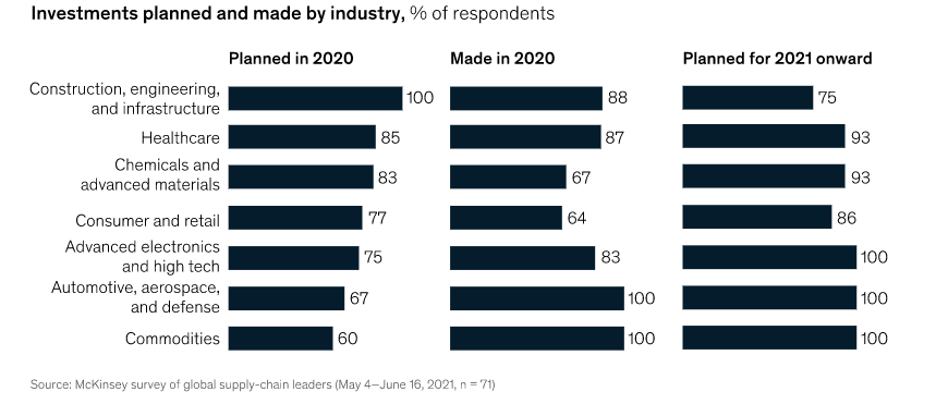

In response, global supply chain leaders plan to invest heavily in technologies that make supply chains more resilient. A recent McKinsey survey shows that significantly more supply chain leaders plan to invest in supply chain technologies in 2021 and beyond compared to those that planned to do so in 2020.

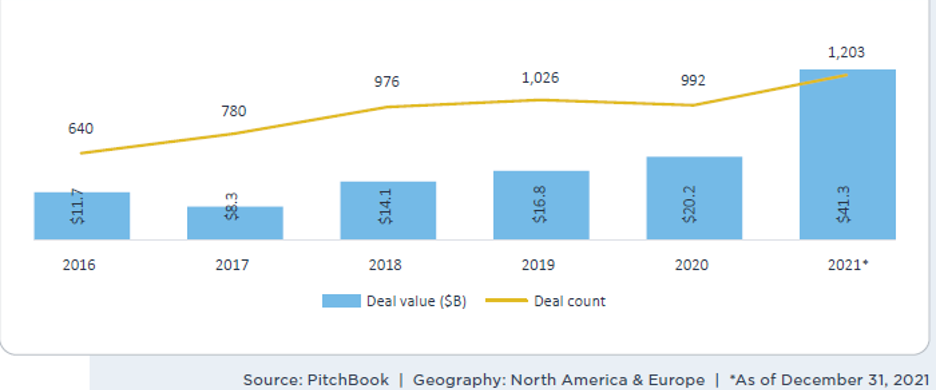

Venture capitalists are responding as well by increasing funding to supply chain tech companies to meet the demand from the industry. In 2021, venture capitalists invested $41B in supply chain tech companies, twice the amount invested in 2020 and significantly more than in the years preceding that.

While the pace of investment in supply chain technology is accelerating, there’s a long way to go, given that the industry is still largely analog, runs on paper, fax and spreadsheets.

Supply chain executives, entrepreneurs and investors recently gathered at Freightwaves’ Future of Supply Chain conference in Arkansas to discuss the state of affairs and evaluate what it will take to move the industry forward. One major theme that emerged from the conference is that the digital transformation now underway in the industry will not only depend on adopting new technology but also on investing significantly in skills development.

This is because the supply chain industry is currently facing a skills gap that threatens to throttle the pace of transformation. Accenture’s research shows that only 38% of supply chain executives feel their workforce is mostly or completely ready to leverage the technology tools provided to them. Any tech company building products for the industry must be aware of this and design its products with ease of use as a top priority.

Trust will be vital here. No matter how useful an innovation is, if potential customers are closed off to it or find it difficult to learn and incorporate in their workflows, it is doomed to become shelfware. Fortunately, additional research from Accenture shows that 78% of executives plan to make a moderate or significant investment in training employees who don’t have expertise in key tools.

Another hindrance to the pace of innovation in supply chain is that the industry tends to be risk averse. This is not for lack of initiative, but rather because the mission-critical nature of supply chains tends to make the industry adopt a conservative stance. Not to mention the fact that some of the pioneering institutions in the industry are approaching their 100th birthday!

Other industries, such as construction, share this same cautious approach when it comes to adopting new technologies. Overcoming this resistance, however, is not impossible. PlanGrid’s success in the construction industry is a recent example.

Before PlanGrid, construction teams would carry paper blueprints around the construction site to guide their work. These blueprints were expensive and quickly became outdated as changes were made on the site. It was impracticable to bring desktop computers or even laptops to construction sites, which usually lack WiFi connectivity. But the arrival of the iPad, in 2010, presented an opportunity. By 2012, PlanGrid had built its app for the iPad and eliminated the need for paper blueprints on construction sites. The form factor of the iPad, the ability of the PlanGrid app to work offline and its ease of use proved to be a winning combination that now saves costs, reduces rework and improves collaboration on construction projects.

The global supply chain shocks of the last few years have been an awakening for consumers and businesses alike. All stakeholders now realize that significant investments in technology will be required to build a resilient supply chain. At the same time, it will be critical for the supply chain industry to invest in training and other programs that enable its workforce to optimize and embrace new technologies to their fullest.

Only the combination of top-notch talent and complementary technology will enable the supply chain industry to achieve its full digital potential. Shelley Simpson, Chief Commercial Officer and EVP at J.B. Hunt, who was a keynote speaker at the Future of Supply Chain conference, summed up this reality well: “A people-first approach is key to developing and executing intelligent and collaborative supply chain solutions.”